Your Partner in Floating Systems

- Based on 10 years of research

- Over 32 hectares designed and build

- One integrator for growing system and automation

What is Floating System?

Floating system

is a cultivation system where crops grow on floating elements, called Floaters, placed in a water ponds. In these Floaters, a substrate is added, on which seeds are sown. The substrate remains above the water, while the roots are constantly submerged. This ensures that the plants have continuous access to water and nutrients while keeping the leaves and substrate dry. The plants always have access to water for transpiration and nutrients for growth. Essentially, the plants have an all-you-can-eat buffet in the water basins.

System Structure

The Floating System consists of a water basin. This basin is created by pouring concrete between greenhouse posts and then lining it with a pond liner. Water is circulated through an inlet and outlet system to the water management unit for disinfection and enrichment with nutrients, ensuring a constant supply of the right amount of water and nutrients.

Features of Floating

The key characteristics include:

- Constant availability of water and nutrients for uniform growth.

- Simple and robust construction that minimizes maintenance and reduces initial investment.

- Robust water buffer, reducing environmental fluctuations or technical malfunctions affecting the plants.

- Scalable and flexible, making the system easy to expand.

- USDA Organic

Crops

With our floating systems, you can cultivate a wide variety of crops, including:

- Baby leaf, teen leaf, spinach and chard

- Head Crops, like butter lettuce, trio lettuce and romain

- Asian Greens such as Pak Choy

- Various Herbs like Mint, Basil, Parsley and Cilantro

Flexibility in Crop Selection and Density

Our systems are designed for both high-quality cultivation and crop diversity. You can easily switch between different crops by simply changing the type of floater. This allows you to adjust plant density per square meter and adapt to market demands without major system modifications. Whether you are growing leafy greens, herbs, or specialty crops, our floating systems provide the adaptability needed for efficient and profitable cultivation.

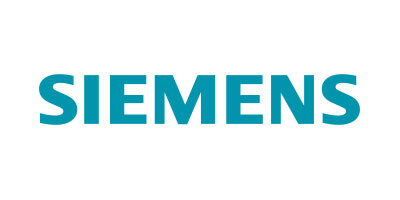

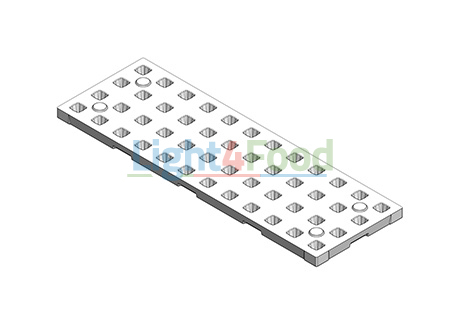

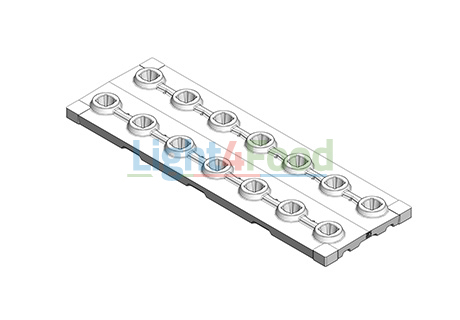

Floaters

We offer standard-sized floaters designed for various crops and planting densities. Depending on the durability, cost, and cultivation goals, we provide floaters made from EPS, EPP, or plastic (blowmold). Together with our customers, we select the most suitable material to optimize their growing system.

Furrow Floaters

Custom-Made and growing media

Custom-Made Floaters for Ultimate Flexibility

In collaboration with our partner Triple Green Innovation, we develop and manufacture custom-made floaters tailored to your specific requirements. By utilizing advanced mold production, we can create floaters that perfectly match your cultivation needs, ensuring maximum efficiency and adaptability.

Whether you need a standard solution or a fully customized design, our floaters provide the flexibility, quality, and innovation necessary for an optimized floating cultivation system.

Growing media

Our floaters are designed to accommodate a variety of growing media, including potting soil, sustainable potting soil alternatives, Jiffy pots, ellepots, paper plugs and pressed pots. This versatility ensures compatibility with different cultivation methods, allowing growers to choose the best substrate for their specific needs.

Growing Facilities

The floating system is designed to suit a wide range of facilities, depending on your needs and budget:

- Poly or plastic greenhouses with more manual operations to reduce investment costs. Ideal for regions with lower labor costs and simpler growing conditions.

- Venlo greenhouses, semi-closed greenhouses, or indoor farms and vertical farms with fully automated systems for maximum efficiency and optimal control over the cultivation process.

We design and build customized solutions that perfectly align with your specific growing environment and local conditions.

The L4F Approach: From Design to Success

At L4F, we work collaboratively to create a customized solution tailored to your needs, ensuring efficiency, flexibility, and long-term growth.

- Co-Design Process – Together, we develop your system based on crop selection, future expansion, and project flexibility.

- Crop Testing – Ensuring optimal cultivation results before implementation.

- Project Specifications – Defining a clear Program of Requirements.

- Engineering & Manufacturing – Precision-built in our own factory.

- On-Site Delivery & Commissioning – Seamless installation at your location.

- Technical & Agronomic Startup – From system setup to optimized cultivation plans and continuous process development.

- Monitoring & Support – Ongoing service, spare parts, and performance tracking.

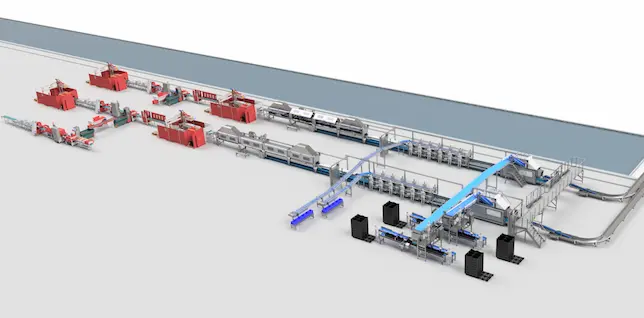

Our integrated turn key solution

When you build your project with us, you get more than just a cultivation system – you get a fully integrated solution that helps your business grow:

- Growing System: We design and manufacture Floaters and optimize them with the design of the facility and automation.

- Automation: Machines and robotics streamline the entire process, from seeding to harvesting, with appropriate technology tailored to your local circumstances and growing goals.

- Water System: An innovative recirculation system that minimizes waste, maximizes efficiency, and supports plant growth by delivering essential nutrients.

- Grow Lights: Light recipes tailored to your crops for maximum yield and quality. More light brings more yield.

8 ha Floating system and machines in USA

2.5 ha Floating system and machines in Germany

6 ha Floating system and machines in USA

Our partners